Master Degree project in collaboration with OneLoop-Stora Enso

Each year, hundreds of tons of furniture are mass-produced, discarded and end up in landfill or being incinerated.

OneLoop was a start-up within Stora Enso providing Large Scale 3D-printing with biocomposite material. In the end of the products lifecycle, OneLoop offered a take-back service which included transport and remanufacturing to reduce waste and use the material over and over again in new production.

OneLoop service

OneLoop Circular Service

Process videos of 3D printing and recyling during my MA Degree project where I had the opportunity to work in the Biocomposite factory located in Hyltebruk, where OneLoop´s production and recycling took place.

Filmed by: Felicia Larsson

Research and Ideation

Prototyping & Production

-

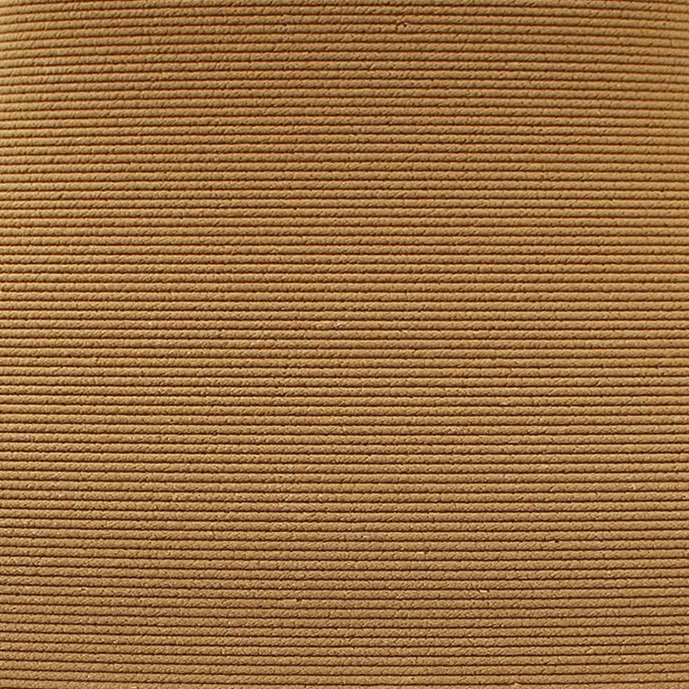

Beach

A pattern created naturally from the 3D printing process, adding layer on top of layer, resulting in a calm and even surface.

-

Shell

A wavey surface that grows larger along the bottom part of the module, resulting in a shell looking pattern.

-

Pebble

An organic and bumpy surface that gives an exra unique look of the module, reminding of small pebble rocks.

Wayflow is an interior concept based on modules that can be arranged in various ways to create different flows and functions in public spaces. The modules can be stacked and save space in transport and storage, making them efficient and suitable for OneLoop´s take-back service.